Redefining Efficiency and Quality in Composite Manufacturing

Precision engineering for high-volume composite manufacturing

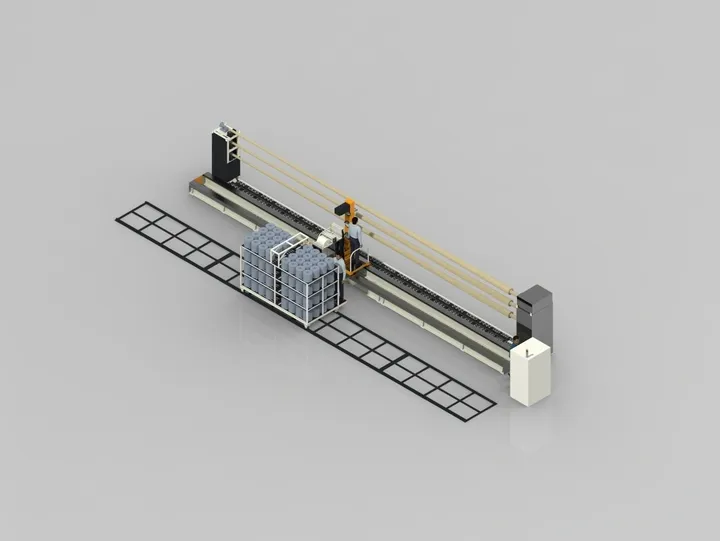

Handles complex winding patterns with multiple filaments simultaneously

Significantly reduces cycle times while maintaining superior quality

Accommodates various composite materials and configurations with ease

Redefining efficiency in composite manufacturing

Simultaneous processing for maximum efficiency

Our multi-spindle filament winding machine represents the pinnacle of composite manufacturing technology. Designed to automate and streamline the process of winding continuous fibers onto mandrels, this specialized equipment creates strong and lightweight composite structures with unprecedented efficiency.

Advanced solutions for diverse manufacturing needs

Lightweight structural components, fuel tanks, and critical parts

Production of composite drive shafts, suspension components, and body parts

Wind turbine blades, structural supports, and energy storage components

Durable, corrosion-resistant marine vessels, masts, and components

Advantages of our multi-spindle technology

Significantly reduces cycle times while maintaining quality standards

Automated fiber cutting, mandrel handling, and real-time monitoring

Seamless integration with real-time data monitoring and predictive maintenance

Discover how our multi-spindle filament winding machines can transform your manufacturing efficiency and quality.